Everything you Need to Know about a DFM Analysis

The DFM analysis is an essential part of your manufacturing journey. Performing one early on in the process will ensure you hit less bumps along the road and avoid major roadblocks. Here’s what you need to know when preparing for a DFM analysis.

Yes, you do need a DFM analysis

Skipping this part of the manufacturing process could end up with costly mistakes and huge delays in getting your product to market. If you are designing a circuit board and need it fabricated, you need a DFM analysis. Designers with years of experience still don’t always know exactly what is needed for a specific process in fabrication.

What happens during a DFM analysis

Engineers will go over your design to make sure it meets all IPC standards and all manufacturing standards. The intention is to provide a robust, consistent circuit that can be duplicated with a high level of trust.

The benefits

The earlier your manufacturing partners can identify issues, the better the results will be for everyone all around. The DFM analysis is where this will happen and you can receive suggestions for changes that can significantly speed up the timing of your project.

How to find the right partner for your DFM analysis

Find a manufacturing partner who specializes in the market which you are developing. They will have the right expertise and can guide you in the best way. Tramonto Circuits specializes in flexible circuits and printed circuit boards. Contact us today to schedule your DFM analysis.

Learn more in our video:

Everything you Need to Know About Flexible Circuits

Whether they know it or not, just about every human has encountered a flexible circuit and more than likely encounters them daily. They play a huge role in manufacturing and Tramonto Circuits has experience with just about every type of flexible circuit. Here is what we can share with you about flexible circuits.

What exactly is a flexible circuit?

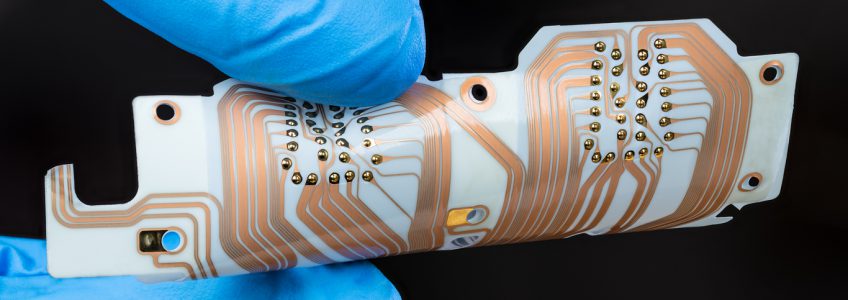

The material that flexible circuits are printed on differs from regular circuit boards because flexible circuits are printed on a plastic polymer. They are thin and light and can be formed to any shape you want, unlike rigid circuit boards.

What everyday products do we use that contain flexible circuits?

Cell phones, laptops, microwaves, automobiles, and so many of the things you touch daily has at least one flexible circuit in it. The computer or mobile device you likely are reading this article on is full of flexible circuits.

What industries most commonly use flexible circuits?

Pretty much every industry uses flexible circuits in one way or another. The automotive and medical industries see them very frequently, but they are showing up almost everywhere now as the world continues to make technology that is smaller and lighter.

What do design engineers need to know about flexible circuit manufacturing?

Designing flexible circuit boards is actually very similar to designing the printed circuit boards that have been worked on for decades. If you’ve been designing printed circuit boards, you already know about 90% of what you need to know to build a flexible circuit. The only differences you have to keep in mind are how the signals move through the bend areas.

Learn more about the flexible circuit capabilities Tramonto Circuits can provide for you.

Watch our video about flexible circuits.

What to Expect From your PCB Manufacturing Partner

When you are trusting your design to a manufacturing partner, your expectations for how you’ll be taken care of should be high. Losing time during the process means losing money on your hard-earned project and your PCB manufacturing partner needs to know that. Here are a few things to keep in mind when choosing the right partner to help you with your PCB design.

They go above and beyond

A good manufacturing partner will keep track of items with longer lead times for you to keep things organized and on schedule. A design engineer’s job is not to keep track of all those things himself or herself.

They stay on or ahead of schedule

A good PCB manufacturer should be able to identify quickly whether a design is going to have a mistake on its first round of boards. Their goal should be to help you get right through to the first round of testing sooner than later.

They deliver on time

On-time delivery seems to be a lost art these days. Tramonto Circuits makes it a priority. We understand that if we don’t deliver to our customers on time, they lose money. A 70% on-time delivery rate is roughly the industry standard. Tramonto Circuits reaches between a 98.15 – 99% on-time delivery rate year after year.

They communicate with your suppliers

You should be able to get intelligent answers from your manufacturing partner. They should be able to speak the language with your suppliers. For assembly partners, they should be able to communicate with your production people and make sure they fully understand the customer experience your product is supposed to deliver.

Learn how Tramonto Circuits has continually exceeded expectations for design engineers since 2008.

What are the Most Common Industries that Utilize Flexible Circuits?

Flexible circuits consist of thin, lightweight electrical circuits that conform to small spaces and contoured 3D shapes including cubes and cylinders. Tramonto Circuits works together with companies in a number of industries to produce high-quality, cost-effective flexible circuits and electronic components to meet their design requirements. We understand that every application is unique and not one size fits all when it comes to circuitry solutions, so we offer a diverse range of solutions for all types of industries. Here are some of the most common industries in which you will encounter flexible circuits.

Consumer Electronics

Items like paintball gun devices, invisible fence dog collars, lighted gift cards, and the fitness trackers and smartwatches you wear include flexible circuits. Tramonto Circuits supplies manufacturers of these products with smaller, lighter, easier-to-use, functional flexible circuits. Current trends tell us that consumers are looking for products that make everyday life more efficient, fun, and flexible and that is our focus when helping design engineers with consumer electronics products.

Medical Devices

The very critical nature of medical devices is not one to leave to chance. In life or death situations, accuracy, dependability, and exceptional quality matter.

Here are just a few of the areas in which Tramonto Circuits is proud to have earned a solid reputation:

- Blood analyzers (used to test COVID-19 virus and antibodies)

- Electric wheelchair safety circuits

- Diagnostic imaging for throat and esophagus

- Medical biological diagnostic equipment

- Medical perfusion machines (keeping organs at body temperature for transplants)

- BioTech Devices for educational labs and classrooms

- Field alcohol detection devices

- Specialized devices used during elective surgeries for pain management and speedier recovery

- Field drug detection devices

Our specialized flexible circuits play vital roles throughout the medical community. They also play a role in transportation, industrial applications, aerospace, and more.

Learn more about Tramonto Circuits’ many industry capabilities and contact us today for a quote.

Tramonto Circuits Achieves Near Perfect On-Time Delivery Rates and Overall Quality Ratio in 2021

Tramonto Circuits has upheld an electronics manufacturing industry reputation of providing on-time delivery to its clients and maintaining a high overall quality ratio for almost 15 years. In 2021, Tramonto Circuits achieved 98.15% on-time delivery and a 99.83% overall quality ratio.

2021 was a challenging year for all industries, especially manufacturing. Supply chain issues and long delays caused headaches all around. Tramonto Circuits was still able to maintain a very good on-time delivery rate against all odds because of its unrelenting commitment to customer service.

“I’m very proud of what we were able to achieve in 2021. The Tramonto Circuits team did an incredible job sticking to our core value, which is to help our customers every step of the way for their unique business solution needs. Our consistent communication, 24-hour quotes, and love for electronics helped us all power through an unprecedented year together,” said John Talbot, President and Owner of Tramonto Circuits.

Contact Tramonto Circuits today to ensure your next manufacturing project is completed to your complete satisfaction.