Single Sided Heaters

Single Sided Heaters

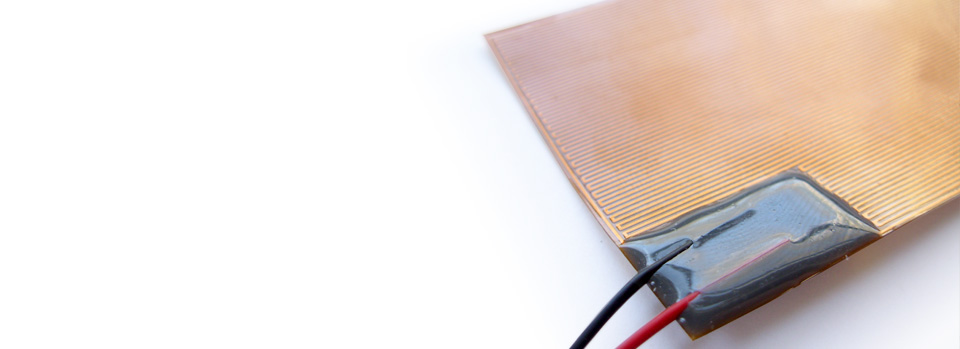

Single sided flexible heaters are the most basic and most widely used of the flexible heater family. They consist of a “single” conductive layer and two insulating layers. These circuits are the thinnest of the flexible heater family with an overall thickness range of 3.7 (.0037”) to 5.4 (.0054”) mils typically. That makes them the most flexible heater construction by definition and therefore they are commonly used in all known heater applications from microprocessor heating to heated mirrors in automobiles. All component types can be attached to single sided heaters and current carrying capabilities of signal traces range from a few milliamps to several amps.

Some Key Points

- Simple and robust construction well suited for applications small and large

- Thin and light weight, yet durable enough for millions of operations

- Wide operating temperature range from ‐55°C ‐ 150°C

- Mount all component types – surface mount (SMT), thru – hole, crimp on pins

- Meets IPC‐6013 Qualifications and Performance Specifications for Flexible Printed Boards

Design Capabilities

- Layer Count: 1 conductive layer

- Trace/Space: determined by heater specifications

- Current Carrying Capacity: few milliamps to several amps

- Hole Size: .008” drilled not plated typical, .004” laser drilled non‐typical

- Conductor Thickness: 1.0 mil, 1.4 mil, 2.0 mil typical

- Material thickness: 1 mil, 2 mil typical, 3 mil and 5 mil non‐typical

- FR4 Stiffener Thickness: .010” ‐ .125”

- Polyimide Stiffener Thickness: .002” ‐ .010”

- Conductor Materials: Copper, Inconel, Constantan, Aluminum