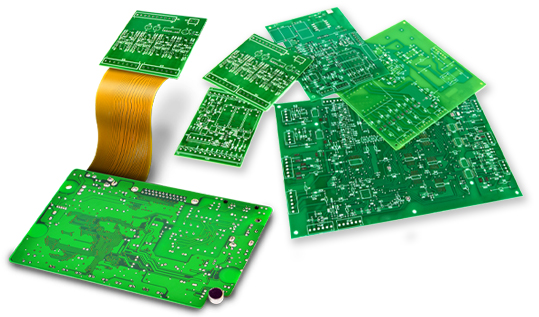

Rigid-Flex PCBs

Rigid-Flex Hybrid Circuits

Rigid-Flex PCBs consist of 2-8 conductive layers and the appropriate amount of insulating layers for that construction. Simple and robust, rigid-flex hybrid circuits combine the advantages of rigid circuit boards and flexible circuits, alleviating the need for extra cables in inventory and assembly.

These circuits are well-suited for interconnect and dynamic applications where accurate location of components is required, while still having the connectivity of a flexible circuit cable.

Manufactured to Your Specifications and Delivered On Time

Bring your design to our team, and we will manufacture and assemble high-quality rigid-flex PCBs with dependable, on-time delivery.

As an ISO 9001:2015 certified rigid-flex PCB manufacturer, we take extra measures to achieve our 99.83% quality ratio. Upon submission, engineers conduct a design for manufacturability assessment. In-process quality checks occur at every manufacturing stage, and 100% of your rigid-flex PCBs undergo a final inspection before shipping.

Our experts are committed to exceeding your expectations for quality and reliability. With a 99.4% on-time delivery rate, you can feel confident knowing you will receive high-quality circuits when you need them.

Key Points & Considerations

- An ideal solution if you want to reduce assembly time and the number of parts in your inventory

- All component types can be assembled to rigid-flex PCBs: surface mount (SMT), thru-hole, crimp-on pins, wire bond, BGA

- Thin and lightweight, yet durable enough for millions of operations

- Wide operating temperature range from ‐55°C ‐ 150°C

- Meets IPC‐6013 Qualifications and performance specifications for flexible printed boards

Design Capabilities for Rigid-Flex PCBs

- Layer Count: 2-8 layers

- Trace/Space: .004”/.004” typical, .003”/.003” non‐typical

- Current Carrying Capacity: a few milliamps to several amps

- Hole Size: .008” drilled, not plated; .006” drilled and plated

- Copper Thickness: ¼ oz, ½ oz, 1 oz, 2 oz typical

- Flex Circuit Material Thickness: 1 mil, 2 mil typical, 3 mil and 5 mil non‐typical

- FR4 Material Thickness: .020, .031”, .062”, .093” and .125” typical