Sculpted Finger Circuits

Sculpted Finger Circuits

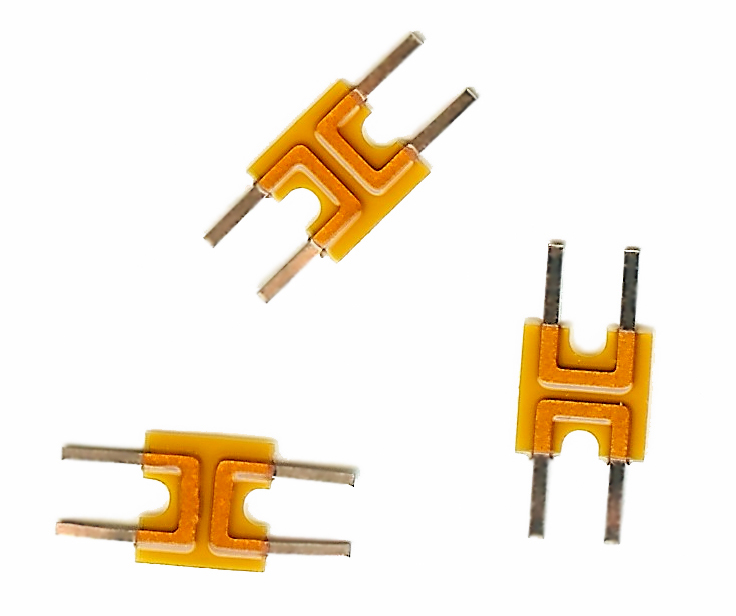

Sculpted finger flexible circuits are unique to the flexible circuit family. They consist of a “single” conductive layer and two insulating layers very much like a single sided circuit. The unique difference is that the conductive layer is made up of .010” thick copper. This allows us to create “sculpted” fingers that extend from the outline of the circuit and create an inherent connector. These circuits, although a part of the flexible circuit family are not very flexible. They are much thicker than typical single sided circuits with an overall thickness of about 16 (.016”) mils typically. Their advantage is not their flexibility, but their intrinsic connector. They are typically used as shunts or board to board connections.

Some Key Points

- Complex and tedious fabrication process

- Heavy construction provides robust method of connecting board to board

- Wide operating temperature range from ‐55°C ‐ 150°C

- Intrinsic connector fingers for direct attachment to circuit boards

- Heavy construction makes component attachment challenging, but Tramonto has the capability/experience to assemble components reliably.

- Meets IPC‐6013 Qualifications and Performance Specifications for Flexible Printed Boards

Design Capabilities

- Layer Count: 1 conductive layer

- Sculpted Finger Pitch: .10” and .20” typical

- Current Carrying Capacity: few milliamps to several amps

- Hole Size: Not Applicable

- Copper Thickness: .010”

- Material thickness: 2 mil typical