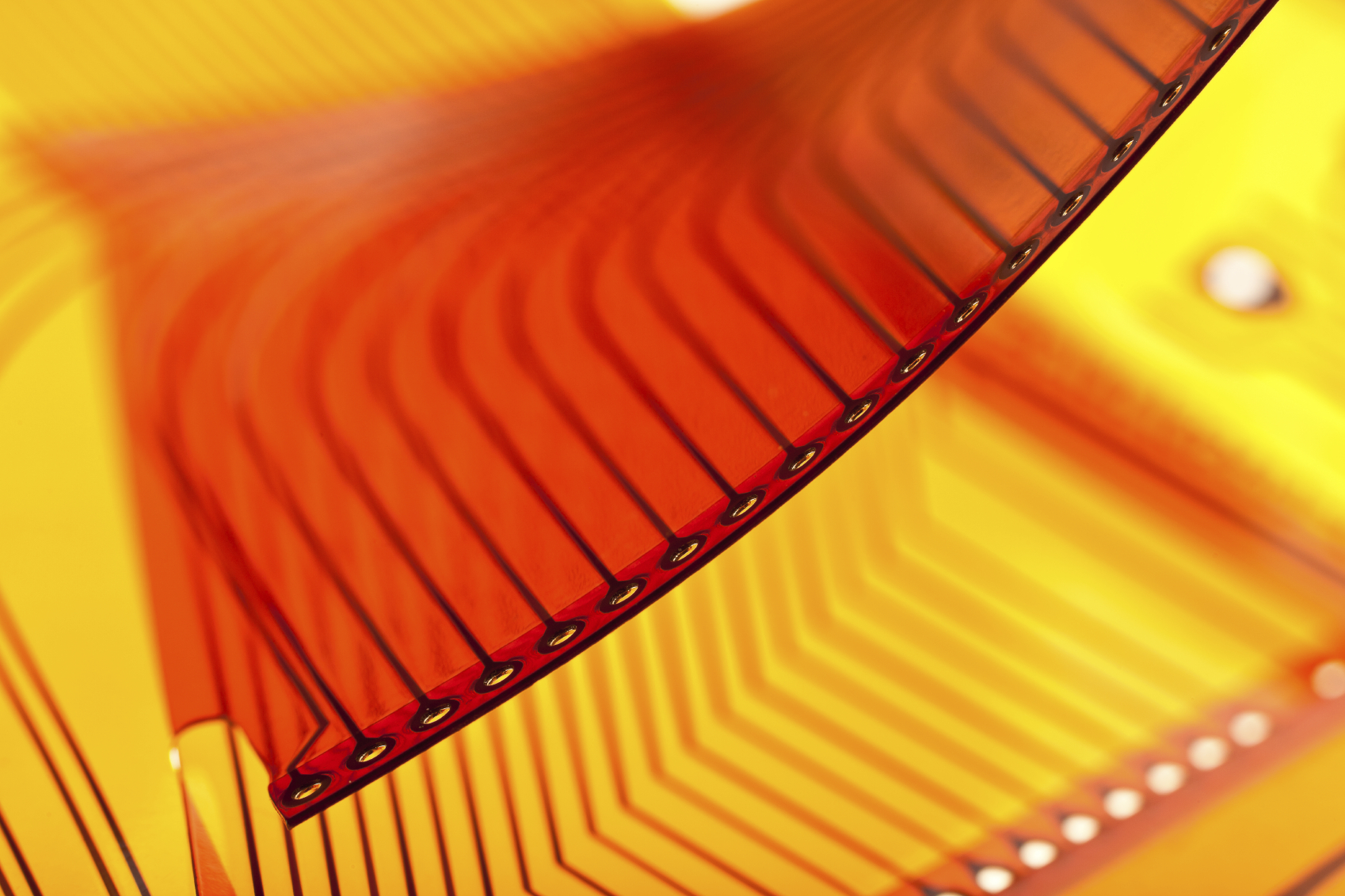

Flexible Circuit Design

Flexible Circuit Design

Tramonto Circuits provides full design service or design assistance for all flexible circuit products. Whether you require us to design the circuit from ground zero or simply need guidance for specific areas of your design, our CAD group is comprised of talented and experienced layout engineers that are happy to support your requirements.

Flexible circuit designs have subtly different specifications than that of their cousin the printed circuit board. Although printed circuit board design is a very well established and taught skill the lack of knowledge or experience with flexible circuits can cause frustration and concern. We have supported our customers’ transition from printed circuit boards to flexible circuits frequently over the years. It’s not as daunting as most think when faced with it the first time and our experienced staff help make the transition as smooth as possible.

Some Key Points

- Full design of flexible circuits

- Support for design or materials specifications

- Robust ZIF connector design

- Protection suggestions for fragile areas of flexible circuit assemblies

- Assure design meets IPC‐6013 Qualifications and Performance Specifications for Flexible Printed Boards